The Ultimate Guide to ANSI Cut Levels and the ANSI Cut Level Chart

In the realm of workplace safety, understanding both the ANSI Cut Level Chart and the materials used in cut-resistant gloves is crucial. This comprehensive guide provides a deep dive into the ANSI cut levels, the materials science behind cut-resistant gloves, and practical advice for selecting the right gloves for your needs.

Understanding the ANSI/ISEA 105-2016 Cut Resistance Standard

The ANSI/ISEA 105-2016 standard, set by the American National Standards Institute, introduces a detailed scale with nine levels to determine the cut resistance of gloves and sleeves. This standard simplifies the selection process for safety equipment by clearly defining the level of protection each product offers against cutting hazards.

Cut resistance is measured on a scale from 0 to 6,000 grams, using the Tomodynamometer (TDM) Method. This method involves moving a blade across the glove material to see how much weight is needed to cut through it. Essentially, the more weight required, the higher the material's cut resistance rating. A product with a higher rating means it offers superior protection against cuts, making it crucial for wearers facing sharp materials or tools in their work environment.

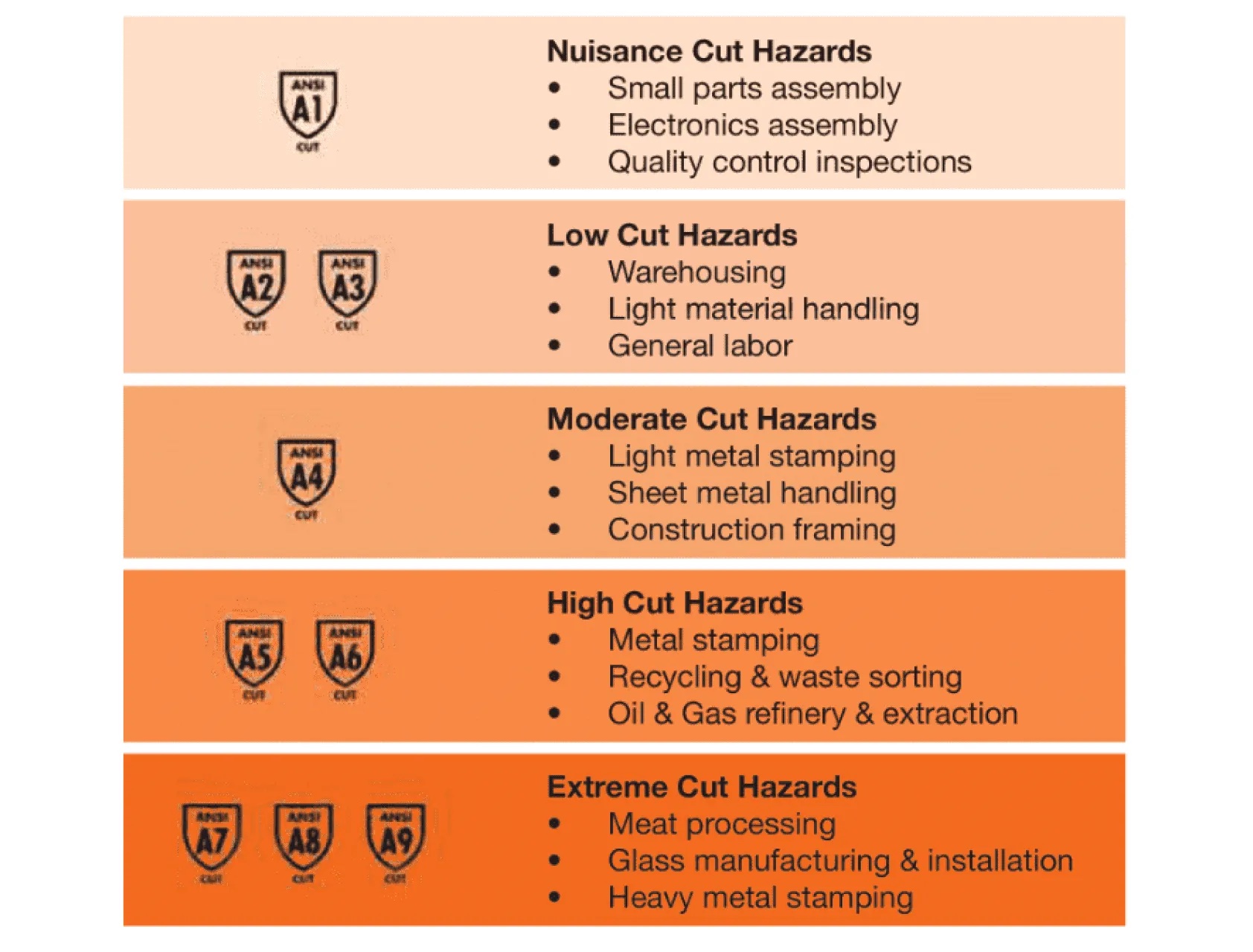

ANSI Cut Level Chart

Hand injuries in the workplace are a prevalent issue, often preventable with the right kind of hand protection. ANSI provides a classification system, known as the ANSI Cut Level Chart, that categorizes gloves based on their resistance to cuts. Coupled with advancements in glove materials, this system is instrumental in helping select the appropriate gloves for various work environments.

Image source: Superior Glove. 'ANSI Impact Chart', retrieved from www.superiorglove.com, November 2023. This chart provides a detailed overview of the ANSI impact standards for protective gloves.

Navigating the ANSI Cut Level Chart

Understanding the ANSI Cut Level Chart is crucial for selecting gloves that provide adequate protection without compromising on dexterity or comfort. This chart categorizes gloves from Level A1, offering minimal cut resistance, to Level A9, designed for the most hazardous environments.

ANSI Cut Level A1 to A2: Light Protection

For activities that pose a low risk of cuts, gloves rated under the first tier of the American National Standards Institute for cut resistance can endure a force of up to 500 grams in slicing tests. These are perfect for handling light materials and assembly tasks.

ANSI Cut Level A3: Moderate Hazards

In situations where there's a medium risk of encountering cuts, gloves that offer Level 3 resistance against cuts present a more robust safeguard, ideal for roles within the construction or automotive sectors where interactions with sharper materials occur occasionally.

ANSI Cut Level A4 to A5: Enhanced Protection

In settings where the potential for cuts is significantly higher, gloves classified between A4 and A5 levels provide essential protection for tasks involving glass, metal, or similar sharp objects.

ANSI Cut Level A6 to A9: Maximum Security

In scenarios where cut hazards are at their most severe, gloves rated between A6 and A9 become indispensable. They play a critical role in sectors such as metal stamping or glass manufacturing, where the threat of significant injuries looms large.

Selecting the Right Cut Level for Your Needs

Choosing the appropriate level of cut resistance is a balancing act between ensuring safety and maintaining work efficiency. Consider the specific tasks and hazards present in your workplace when selecting gloves.

Still not sure what you need? Partner with an Expert!

*Are Cut-Resistant Gloves "Cut Proof"?

While cut-resistant gloves offer significant protection, it's important to know that no glove is completely cut-proof. Gloves are made to be flexible, allowing for easy movement and the ability to put them on and take them off easily. This flexibility means they can't be 100% impenetrable. Even gloves made from strong materials like chainmail can be cut through if someone tries hard enough. However, cut-resistant gloves are designed to greatly lower the risk of cuts. They might not stop all injuries, but they can make a big difference in reducing how severe a cut could be.

Understanding the Science of Cut-Resistant Materials

At the core of cut-resistant gloves is the innovative use of materials engineered to withstand cuts while maintaining flexibility and comfort. Let's explore the materials that set the standard for hand protection.

HPPE vs. Para-Aramid

High-Performance Polyethylene (HPPE) and para-aramid fibers are at the forefront of cut-resistant technology, each offering distinct advantages. HPPE gloves are known for their strength, providing up to ANSI Cut Level A3 protection. They are preferred for their comfort, making them ideal for tasks requiring both protection and dexterity.

Conversely, para-aramid fibers excel in high-temperature environments, offering both cut and thermal hazard protection. These materials are essential for workers in industries where both types of hazards are present.

Composite/Engineered Yarn

To attain the pinnacle of cut resistance, gloves are crafted from composite or engineered yarns, mixing materials like HPPE with steel or fiberglass. This combination ensures a high degree of protection while maintaining comfort and manual agility, reaching up to the ANSI Cut Level A9 standard.

Real-Life Scenario: Glass Factory Worker

Imagine a scenario where a glass manufacturing plant is assessing glove options for their workers. The environment presents a dual hazard: the risk of cuts from handling glass and potential burns from occasional contact with hot surfaces. Here, para-aramid gloves would be the superior choice, offering the necessary cut resistance while also protecting against thermal risks. This decision exemplifies the importance of material selection based on specific workplace hazards.

Conclusion

Combining knowledge of ANSI cut levels with an understanding of the materials used in cut-resistant gloves empowers you to make informed decisions about hand protection in the workplace.

Join our Save-ty Club for exclusive deals and safety news. Sign up here.

Share this article on social media and tag us for a special discount on your next purchase.

Let's spread the word on staying safe!

Disclaimer: The content provided on this website is for informational purposes only and is not intended to be a substitute for professional medical advice, diagnosis, or treatment. Always seek the advice of your physician or other qualified health provider with any questions you may have regarding a medical condition.

The information on this site should not be construed as establishing any safety standard or as providing directives for compliance with the Occupational Safety and Health Administration (OSHA) or any other health and safety regulatory agencies. Reliance on any information provided by this website is solely at your own risk. We do not accept any responsibility for any loss which may arise from reliance on information contained on this site.